Abstract

The photocatalytic conversion of an aqueous solution of l-tryptophan (Trp) to kynurenine (KN) was investigated under the illumination of different light sources. Results show that Trp converted to KN with a selectivity of 64% under the illumination of a medium pressure (MP) Hg lamp. KN selectivity was increased to >90% when black light (BL) was used a light source. The novel use of BL in the photocatalytic conversion of Trp to KN significantly reduces the energy consumption compared with MP light.

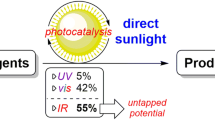

Graphical Abstract

Similar content being viewed by others

1 Introduction

Ultraviolet radiation (UV) has been used for several years in the disinfection of air or in water treatment together with TiO2 (photocatalysis) or with H2O2 (photolysis) [1]. Palmisano [2] discussed the importance of the replacement of hazardous processes with selective photocatalysis as a promising strategy in the 21st century. Moreover; there are a number of recently published reviews on such an approach in specific chemical synthesis [3, 4]. Several reactions have been reported that can be performed selectively by photocatalysis such as some oxidation and reduction reactions [5]. Other reactions such as cyclisation and carbonylation can also be carried out [6].

Of particular interest within the context of this article is the control and selectivity in the effect of photolysis and photocatalysis on amino acids and their conversion to functionalized building blocks. Investigations into the stability and reactivity of amino acids under the influence of UV (sunlight) have been generally limited to the context of physiological toxicity or evolution and exploited to a limited extent as a synthetic tool [7, 8]. However, the selective cyclization of lysine and conversion of glutamic and aspartic acids to succinic and malonic acids, respectively have been described [9, 10]. Others have reported the response/decomposition of amino acids in a photocatalytic UV/TiO2 system although the products were not identified [11, 12].

Due to their chemical make-up, many amino acids may be useful precursors for preparing (highly) functionalised chemicals traditionally prepared by the petrochemical industry [13]. As a consequence of fluctuating oil prices and attempts to curb CO2 emissions, scientists and governmental bodies are aiming to replace fossil feedstocks for transportation fuels and chemicals with renewable, emission neutral raw materials and develop new efficient process routes. It is anticipated that the level of substitution of petrochemical transportation fuels with bio-fuels will rise in the coming years; thus, with this increase in the production of bio-fuels, large and excess quantities of proteins will be generated that could be used as amino acid feedstocks. One synthetically useful amino acid is tryptophan. Potentially the conversion of tryptophan via kynurenine to anthranilic acid [14, 15], followed by decarboxylation [16, 17] may lead to the formation of biobased aniline, Fig. 1 [18]. Aniline is traditionally produced by the nitration of benzene and used in the synthesis of 4,4-methylenediphenyl diisocyanate (MDI), which is used as a monomer in polyurethane foams.

Kynurenine is a known product formed in the metabolic pathway of tryptophan. Indoleamine 2,3-dioxygenase (IDO) and l-tryptophan 2,3-dioxygenase (TDO) convert tryptophan to N-formyl kynurenine and then using kynurenine formamidase to kynurenine [19–21].

Chemical formation of kynurenine from tryptophan is known. In particular the oxidation of tryptophan using peracetic [22] or performic acid [23] has been examined which resulted in the formation of kyurenine. The presence of anthranilic acid was also noted.

The ozonolysis of tryptophan yields N-formylkynurenine [24, 25]. However, in other publications, it was reported that kynurenine is also produced together with N-formylkynurenine [26, 27]. Hence, a deformylation step is needed to convert N-formylkynurenine to kynurenine. Moreover, the ozonolysis of N-acetyltryptophan followed by acidic hydrolysis produce kynurenine sulfate [28].

Tryptophan spontaneously absorbs UV from the sun in a wavelength range 240-310 nm and converts slowly to kynurenine. The photochemical activity of tryptophan has been studied to investigate the effect of sun on the amino acids [29, 30] and the phenomenon of wool yellowing on exposure to sunlight [31–33]. More specifically, the formation of kyurenine, and other products, formed by the photochemical degradation of tryptophan has been reported [34, 35].

In the present work, we have studied the photocatalytic conversion of tryptophan to kynurenine as a synthetic tool. Here the use of two different light sources; a medium pressure (MP) Hg-vapor illumination and a black light (BL) illumination were studied in order to obtain a straightforward, high yielding, specific and improved cost-effectiveness for the formation of kynurenine with high purity.

2 Experimental

2.1 Materials

Tryptophan (Fluka, 99.5%), kynurenine (Sigma-Aldrich, 99.5%) and TiO2 (Degussa P25, 97%) were used as obtained without any further purification.

2.2 The Photocatalytic Activity Study

The photocatalytic activity measurements were carried out in two different systems. Photo-reactor I is an 850 ml cylindrical slurry-type batch reactor (UV-Consulting Peschl, Germany). The UV irradiation was delivered by a medium pressure Hg lamp (150 W), the wavelength distribution of the lamp is illustrated in Fig. 2 (Left panel). The lamp is surrounded by a quartz cooling jacket to maintain the reaction temperature at 25 ± 2 °C. Air was bubbled through the solution with a constant flow rate (20–25 ml/min) in all the experiments with a stirring rate of 700–900 rpm. In a typical experiment, 850 ml of an aqueous tryptophan solution (0.2 g/l) was placed in the reactor. The solution was stirred first for 20 min and then the MP UV Hg lamp was illuminated for 2 h. Samples were withdrawn at constant time intervals (filtered through a 0.45 μm PTFE Millipore membrane filter to remove suspended agglomerates, only in the case of TiO2 added) and analyzed by means of UV–Vis spectrophotometer and HPLC.

Photo-reactor II is a purpose built black light reactor. The reactor is made of an aluminum box (60 cm height, 60 cm width, 40 cm depth) which was equipped with a 12 V transformer for an electric exhausting fan and eight black light tubes (F20 T8 BLB, 18 W, 60 cm × 2.5 cm) of approximately 350-400 nm (Fig. 2, right panel) and each lamp may be independently controlled. A magnetic stirrer was used to stir the reaction mixtures during the experiment. The experiments were carried out in open glass beakers (height 8 cm, volume 100 ml). In a typical experiment, 50 ml of aqueous solution of tryptophan (0.2 g/l) was placed in the beaker, aerated (20–25 ml/min) and stirred (700–900 rpm) during the course of the experiment. The solution was stirred initially for 20 min in the dark, and then the black light lamps were illuminated for 2 h. Samples were withdrawn at constant intervals filtered by micro-membrane and analyzed by means of HPLC.

2.3 Analysis

2.3.1 UV–Vis Spectrophotometer

The absorbed UV–Vis spectrum was recorded using a CaryWin 300 spectrometer with Milli-Q water as a reference. Samples were scanned from 200 to 800 nm. The absorption spectra of tryptophan and kynurenine are given in Fig. 3.

2.3.2 HPLC

Waters 2487 dual absorbance detector (215 nm and 260 nm) was used for sample analyses. The column Waters X-bridge, C18 5 μm 3.0 × 150 mm was applied and kept at a temperature of 40 °C with a constant flow of 0.6 ml/min.

3 Results

3.1 The Photo-(Catalytic) Activity of Tryptophan

To investigate the effect of the UV radiation delivered by the medium pressure Hg lamp on tryptophan, an aqueous solution of tryptophan was placed in photo-reactor I and subjected to illumination for 2 h. Figure 4 shows the conversion (mol %) of tryptophan as a function of irradiation time. Tryptophan showed considerable photolysis activity, almost 50 mol % of tryptophan being converted within 2 h. The detected products were kynurenine, hydroxytryptophan, hydroxykynurenine, and traces of N-formylkynurenine. Selectivity towards kynurenine was 64 mol %.

To study the effect of aeration during the photolysis of tryptophan, a separate experiment was carried out under the same experimental conditions described above but without aeration. It was also observed that aeration during the photolysis improves tryptophan conversion from 37 to 50 mol% due to the need for oxygen in the photo-conversion process. In another experiment, tryptophan solution was stirred with TiO2 for 2 h without light illumination; no conversion was observed.

The photocatalytic conversion of tryptophan solution was measured with different amounts of TiO2 catalyst under the illumination of the medium pressure Hg lamp. When 50 mg of TiO2 was added to 1 l of an aqueous tryptophan solution (0.2 g/l), a conversion of 57 mol% was obtained with 60 mol% selectivity towards kynurenine (Fig. 4). When experiments with higher TiO2 concentration (100 and 200 mg/l of substrate) were carried out, tryptophan conversion increased (65 and 67 mol%, respectively), however selectivity towards kynurenine decreased to 52 and 48 mol%, respectively (Fig. 5). Hence, using higher TiO2 concentration is not useful to improve the tryptophan conversion as selectivity is decreased.

Contrary to its behavior under medium pressure lamp illumination, an aqueous solution of tryptophan did not show any photolytic activity under the illumination of the black light lamps for a period of 8 h (see Fig. 4, for comparison the photolysis activity during the first 2 h was only plotted). Moreover, TiO2 did not exhibit any catalytic activity in the absence of light illumination.

When 50 mg of TiO2 was added to 50 ml of aqueous tryptophan solution (0.2 g/l) and stirred under the illumination of the eight black light lamps, 52 mol% of tryptophan was converted with >90 mol% selectivity towards kynurenine. Here the measured distance between the surface of tryptophan solution and the nearest illumination point was 12 cm. Decreasing the distance to 8 cm resulted in an increase in the conversion of tryptophan to 69 mol% whilst a further decrease in distance to 5 cm (that was the shortest possible distance due to some technical restrictions) led to a further increase in the conversion to 73 mol%. These results show that conversion is affected by the distance between the reaction solution and the point of illumination: as the distance becomes shorter the better the conversion, without affecting the kynurenine selectivity. The lower distances shortens the travelling distance of photons and prevents photon dispersion.

The amount of photocatalyst was also optimized where 1 g of TiO2 per 1 l of aqueous tryptophan solution (0.2 g/l) showed the maximum tryptophan conversion. When the applied concentration was higher than 1 g/l, the tryptophan conversion was decreased due to the shielding effect, where photons cannot penetrate to a long distance inside the solution due to the high concentration of substrate and/or the catalyst [36].

To determine the optimum amount of light which reaches the solution, a set of three experiments were carried out. 50 ml of 0.2 g/l aqueous tryptophan solution was stirred together with 50 mg of TiO2. The distance between the surface of solution and the light source was kept constant at 5 cm and the number of lamps illuminated the experiments varied: 1, 3, and 8 lamps. From Fig. 7 it can be seen that with one lamp illuminated a conversion of 42 mol% of tryptophan with 92 mol% selectivity towards kynurenine within 2 h was achieved. When this was increased to three lamps being used, 70 mol % of tryptophan was converted with 90 mol % selectivity towards kynurenine. Finally, increasing the number of lamps used to eight resulted in 72 mol% conversion of tryptophan with a selectivity of 90 mol % for kynurenine. The obtained tryptophan conversion and selectivity by using photo-reactor I is compared with its conversion by the photo-reactor II in Fig. 6.

3.2 The Photo-(Catalytic) Stability of Kynurenine

As shown above, tryptophan is photo-(catalytically) converted to kynurenine as a major product and other minor products. To study the photo-(catalytic) stability of the formed kynurenine, several experiments were carried out. In this section, the results of photo-(catalytic) stability of kynurenine will be shown.

Kynurenine exhibits high photolysis stability either under the medium pressure Hg lamp or black light lamp(s). When an aqueous solution of kynurenine (0.2 g/l) was kept for 2 h under illumination light; 2.7 mol% of kynurenine was converted under the medium pressure Hg lamp, and less than 1 mol% was converted under the illumination of black light (Fig. 7). In the presence of TiO2 (200 mg/l for Hg lamp and 50 mg for the black light) a conversion of 7.2 and 4.4 mol% was obtained; respectively. The main identified product was hydroxykynurenine.

4 Discussion

4.1 The Photo-(Catalytic) Conversion of Tryptophan to Kynurenine

Tryptophan is the most photochemically active amino acid because it has a greater capacity for absorbing photons in the UV-B region of the electromagnetic radiation spectrum than any other aromatic amino acid [37].

Results obtained from the photolysis experiments of tryptophan clearly support this view. 50 mol% of aqueous tryptophan solution (0.2 g/l) was converted within 2 h under the illumination of the medium pressure Hg lamp in the presence of oxygen. This lamp exhibits a remarkable irradiation in the UV-B region as shown from its wavelength distribution spectrum (Fig. 2) and hence tryptophan molecules can absorb photons with this energy and react. As a result of the photochemical oxidation of tryptophan; kynurenine—the desired product—is produced with a selectivity of 64 mol%, other compounds such as hydroxytryptophan, N-formylkynurenine, and Hydroxykynurenine were also detected. These compounds were also detected in previous publications [38, 39].

Results showed the photochemical oxidation of tryptophan in aqueous solution is accelerated to a higher extent when it is photocatalyzed by TiO2. The tryptophan conversion increased from 50 mol% with UV only to 67 mol% when 200 mg of TiO2 was added. However, kynurenine selectivity decreased from 64 to 48 mol% (Fig. 5). This can be explained by the over-oxidation reaction of kynurenine to hydroxykynurenine which is most likely promoted by TiO2. Experimental evidence was obtained for this assumption when an aqueous solution of kynurenine (0.2 g/l) was photocatalyzed by 200 mg of TiO2 for 120 min; a conversion of >7 mol% was obtained and the main product detected was hydroxykynurenine.

Tryptophan did not show any photochemical activity under the illumination of the black light lamps. This is logical since the black light does not exhibit any irradiation in the UV-B region. The black light exhibits irradiation in the range of 350–400 nm, i.e. UV-A or long wave (Fig. 2). Moreover, black light was found to be a good source to photo-activate TiO2 [40]. Hence; if a system contains aqueous tryptophan solution, TiO2 and illuminated with black light; the tryptophan conversion will be due to the photocatalytic reaction only.

The concentration of the photo-catalyst used in the black light reactor (50 mg/50 ml substrate) was 5 times higher than the amount used in MP reactor (200 mg/1 l substrate). This can explain the obtained high photocatalytic conversion of tryptophan under the black light illumination (Fig. 4). Moreover, the competing of the photolysis products to absorb photons from tryptophan might be another reason. More interestingly, the selectivity towards kynurenine was >90 mol% in all the performed experiments. Small amounts of N-formylkynurenine and hydroxykynurenine were detected as well. This higher selectivity can be explained by the exclusion of the photochemical reactions that take place under MP Hg-lamp illumination e.g. the conversion of tryptophan to hydroxytryptophan.

Kynurenine was believed to be a photochemically inert compound for a long time. The singlet excited state of kynurenine relaxes to the ground state on the pico-second time scale [41]. Recent studies showed that an aqueous kynurenine solution upon UV irradiation produces the long-lived kynurenine intermediate, namely, triplet excited state [42]. The reactivity of the triplet state is low, and one of the channels of the triplet decay is to return to the ground state by oxygen quenching [43] as in our case.

In general, the photodecomposition of kynurenine has low quantum yield [44, 45]. Practically, photolysis of kynurenine did not show significant conversion within the first 2 h either under the illumination of the medium pressure light source or the black light source. This result is in good agreement with the previous work of Tsentalovich in which a very small amount of kynurenine (>3 mol%) was decomposed under the high pressure Hg lamp [43]. By prolonging the photolysis of kynurenine, almost 18% was converted within 10 h under the medium pressure illumination and around 10% conversion under black light illumination. Thus, to obtain a high kynurenine yield, the photo-(catalytic) conversion period should not exceed 2 h in order to avoid the over-oxidation of kynurenine.

The photochemical conversion of tryptophan was proposed earlier in [46, 47]. Tryptophan is rapidly absorbing UV photons and being excited; a radical tryptophan cation is formed (1) by charge separation, while the hydrated electron transfers to oxygen to form superoxide anion (2). Thus, N-formylkynurenine is formed through the reaction between superoxide anion and the radical tryptophan cation (3). Finally, N-formylkynurenine is unstable and deformylated either by a hydration process (4) [47] or by the effect of UV [48] to form kynurenine and formic acid.

In the presence of TiO2 together with a UV illumination source in the UV-B region, TiO2 and tryptophan will absorb photons and activate, electron–hole separation will take place on TiO2 crystals (5), and tryptophan will form the tryptophan cation (1). Electrons either from (1) and/or (5) will form with oxygen the superoxide anion that will form NFK (3).

If the illumination source can activate only the photocatalyst e.g. black light, the hydroxyl radicals are believed to attack the double bond in tryptophan (between carbon 2 and 3) and the pyrrol ring will open [49, 50]. The superoxide anion will oxidize these to carbon atoms to form NFK (8) [47]. Currently, an IR study is carrying out for further mechanism investigation.

4.2 Electrical Energy Determination

One of the important factors in selecting the AOP (advanced oxidation process) technology as a synthetic tool is the economics. Since photo-(catalytic) conversion of aqueous organic solutions is an electric-energy-intensive process, and electric energy can represent a major fraction of the operating costs, simple figures-of-merit based on electric energy consumption can be very useful and informative. Electrical Energy per order (E Eo ) is calculated to express the amount of kilowatt/hours of electricity required to reduce the concentration of a compound by 1 order of magnitude.

where P is the rated power (kW) of the advanced oxidation process AOP system, t is the irradiation time (min), C i and C f are the initial and final pollutant concentrations, V is the volume (l) of the water in the reactor. Energy price calculated as 0.2 euro/kilowatt (domestic price, Eneco, NL).

The obtained results were listed in Table 1.

Clearly, the energy cost could be reduced by optimization of the number of illuminated black light lamps. In general, the black light seems to be a better choice for the photocatalytic conversion of tryptophan for kynurenine production. A better reactor design would be needed to achieve the best conversion.

5 Conclusions

From this study, the following conclusions can be drawn: (a) The photolysis of tryptophan is not selective, kynurenine, hydroxytryptophan, hydroxykynurenine, and N-formylkynurenine are formed. (b) The photocatalysis of tryptophan by using TiO2 (P25) and MP Hg lamp as a light source is not selective too because the interfering of photolysis reaction. (c) The use of black light as a light source improves the selectivity towards kynurenine to more than 90%. (d) The use of black light was shown to be economically feasible.

References

Reddy SS, Kotaiah B (2005) Int J Environ Sci Technol 2:245

Palmisano G, Augugliaro V, Pagliaro M, Palmisano L (2007) Chem Commun 3425

Teply F (2011) Collect Czech Chem Commun 76:559

Palmisano G, Garcia-Lopez E, Marci G, Loddo V, Yurdakal S, Augugliaro V, Palmisano L (2010) Chem Commun 46:7074

Ravelli D, Dondi D, Fagnoni M, Albini A (2009) Chem Soc Rev 38:1999

Shiraishi Y, Hirai TJ (2008) J Photochem Photobiol C 9:157

Waddell TG, Miller TJ (1992) Origins Life Evol Biosphere 21:219

Ansari AS, Khan IA, Ali R (1985) J Radiat Res 26:321

Ohtani B, Pal B, Ikeda S (2003) Catal Surv Asia 7:165

Giri KV, Kalyankar GD, Vaidyanathan CS (1953) Naturwiss 40:440

Trung H, Nosaka AY, Nosaka Y (2006) J Phys Chem B 110:25525

Hidaka H, Horikoshi S, Ajisaka K, Zhao J, Serpone N (1997) J Photochem Photobiol A 108:197

Scott E, Peter F, Sanders J (2007) Appl Microbiol Biotechnol 75:751

Kumagai H, Tochikura T, Kanisawa T (1990) JP 02135093

Stanier RY, Hayaishi O (1951) J Bacteriol 62:367

McCollough W, Piligan JT, Daniel I (1957) J Am Chem Soc 79:628

Takemura Y, Nakamura A, Taguchi H (1985) Ind Eng Chem Prod Res Dev 24:213

Sanders J, Peter F, Scott E, Hamdy MS, Carr R (2011) US0045553

Musajo L, Benassi CA (1964) Adv Clin Chem 7:63

Price JM, Brown RR, Yess N (1965) Adv Metab Disord 2:159

Wolf H (1974) Scand J Clin Lab Invest Suppl 136(1):18

Ohno M, Spande TF, Witkop B (1974) J Org Chem 39:2635

Benassi CA, Scoffone E, Veronese FM (1965) Tetrahedron Lett 49:4389

Knox WE, Mehler AH (1950) J Biol Chem 187:419

Kotiahoa T, Eberlinb MN, Vainiotaloc P, Kostiainen R (2000) J Am Soc Mass Spectrom 11:526

Masuda N, Sakiyama F (1977) Pept Chem 14:41

Mudd JB, Leavi R, Ongun A, Mcmanus TT (1969) Atmos Environ 3:669

Warnell JL, Berg CP (1954) J Am Chem Soc 76:1708

Andley UP, Clark BA (1989) Invest Ophthalmol Vis Sci 30:706

Dillon J, Chiesa R, Spector A (1987) Photochem Photobiol 45:147

Schäfer K, Goddinger D, Hocker H (1997) J Soc Dyers Colour 133:350

Asquith RS, Hirst L, Rivett DE (1971) Appl Polym Symp 333

Asquith RS, Rivett DE (1971) Biochem Biophys Acta 252:111

Obata Y, Sakamura S (1954) Nippon Nogeik Kaishi 28:768

Sakamura S, Obata Y (1955) Nippon Nogeik Kaishi 29:817

Rincón AG, Pulgarin C (2003) Appl Catal B 44:263

Lin MF, Tzeng CM, Dyakov YA, Ni CK (2007) J Chem Phys 126:241104

Dyer JM, Bringans SD, Bryson WG (2006) Photochem Photobiol Sci 5:698

Dyer JM, Bringans SD, Bryson WG (2006) Photochem Photobiol 82:551

Tanizaki T, Murakami Y, Hanada Y, Ishikawa S, Suzuki M, Shinohara R (2007) J Health Sci 53:514

Dillon J, Atherton SJ (1990) Photochem Photobiol 51:465

Tsentalovich YP, Snytnikova OA, Sherin PS, Forbes MDE (2005) J Phys Chem A 109(3565):19

Sherin PS, Tsentalovich YP, Snytnikova OA, Sagdeev RZ (2008) J Photochem Photobiol B 93:127

Krishna CM, Uppuluri S, Riesz P, Zigler JS, Balasubramanian D (1991) Photochem Photobiol 54:51

Dillon J, Wang RH, Atherton SJ (1990) Photochem Photobiol 52:849

Snytnikova OA, Sherin PS, Kopylova LV, Tsentalovich YP (2007) Russ Chem Bull 56:732

Kazakov VP, Ostakhov SS, Osina IO, Alyabev AS, Kavsarova IF, Akhmadeeva GK (2006) Radiochem 48:456

Hardeland R, Tan D, Reiter RJ (2009) J Pineal Res 47:109

Van de Weert M, Lagerwerf FM, Haverkamp J, Heerma W (1998) J Mass Spectrom 33:884

Maskos Z, Rush JD, Koppenol WH (1992) Arch Biochem Biophys 296:514

Acknowledgments

The project was financially supported from Huntsman Corporation. The authors gratefully thank A. van Zeeland for the HPLC measurements and F. Claassen for LC–MS.

Open Access

This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Hamdy, M.S., Scott, E.L., Carr, R.H. et al. A Novel Photocatalytic Conversion of Tryptophan to Kynurenine Using Black Light as a Light Source. Catal Lett 142, 338–344 (2012). https://doi.org/10.1007/s10562-012-0775-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-012-0775-7